Attention:

Please note that operations of the Fishing Echo Sounder Simrad EK 80 requires experienced scientific staff on board and can be only operated on request. The system is not operated by the ship's crew. Request operations with the Fishing Echo Sounder Simrad EK 80 to AWI-Logistics in sufficient time prior to the cruise and clarify the data transfer after the cruise.

Data quality of Fishing Echo Sounder Simrad EK 80 is decreased by operating other Echo Sounders. Repeatable disturbances were detected from simultaneously operating a) POSIDONIA, b) Sonar Doppler Speed Log DOLOG and c) Sediment Echo Sounder Parasound P70. Switch off these Echo Sounders for high data quality.

Summary

The sounder operates several frequencies simultaneously thus allowing to detect fish in different depths.

| Manufacturer | Kongsberg |

|---|---|

| Model | Simrad EK 80 |

| Serial No. | n/a |

| Type | echo sounder |

| SENSOR-Link | ↪ |

Transducer Frequency:

Contacts

| Name | Institution | Role |

|---|---|---|

| Sören Krägefsky | Alfred Wegener Institute, Helmholtz Centre for Polar and Marine Research | Engineer In Charge, Principal Investigator, Data Scientist |

| Alfred Wegener Institute for Polar and Marine Research | Alfred Wegener Institute, Helmholtz Centre for Polar and Marine Research | Owner |

Components

Subdevices

Position

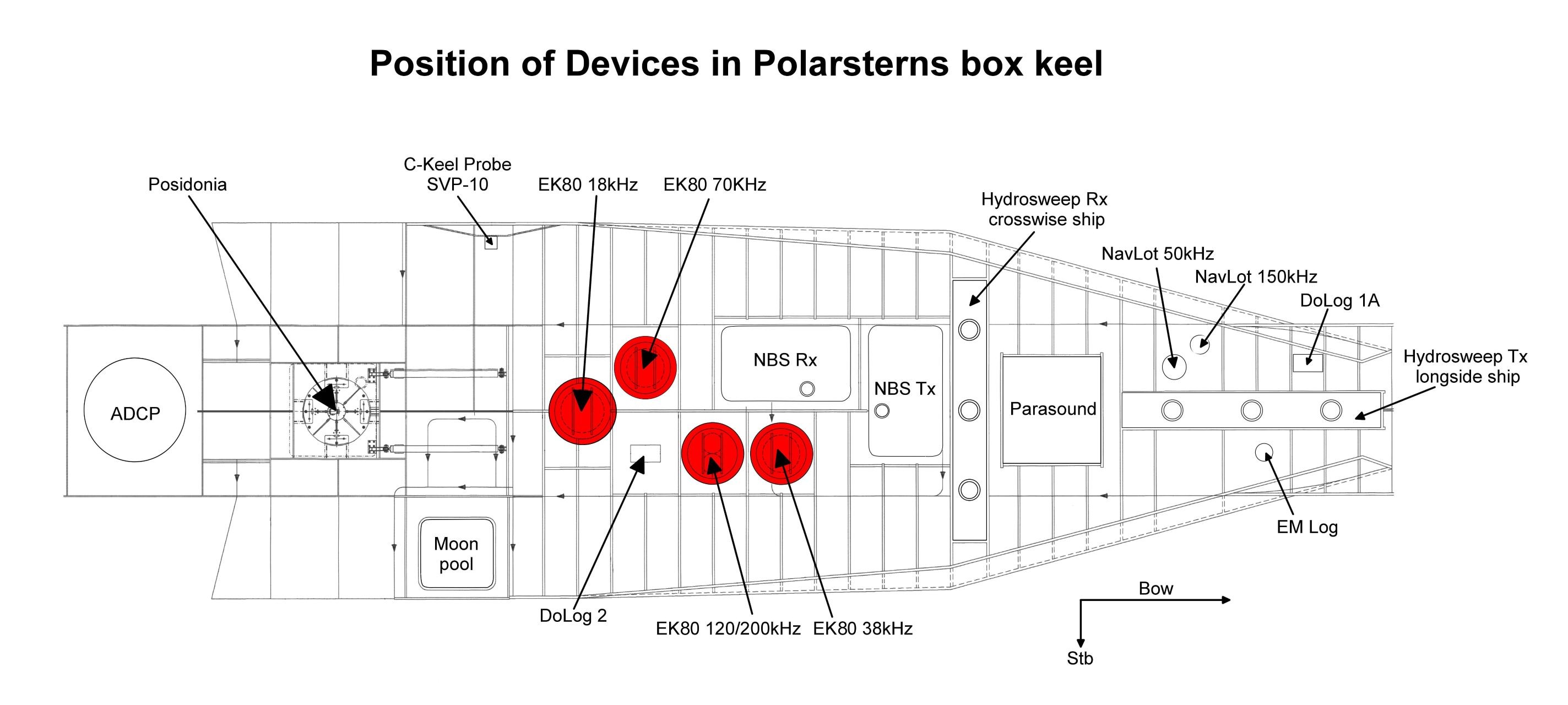

| Info | xyz-position calculated from Alignment Survey Report RV Polarstern (2016), transducers located in box keel, electronics located in E525, computers located in A113 |

| X | 73.14 m (X-0 is at the center of der rudder (ref. design drawing of the vessel), positive X-axis is forward and along vessel centerline) |

| Y | 0.022 m (Y-0 at centerline, positive Y-axis is portside ) |

| Z | 0.012 m (Z-0 is set to the lowest point of the keel, positive Z-axis is upwards) |

Data logging, storage and archiving

Logged parameters

| Parameter | Sensor Output Type | Unit |

|---|---|---|

| depth | depth | m |

Central geographical ship's position and time standard

The geographical ship's position is transferred to the Master PC together with the NMEA-String and to the data files. There is no centering of the GPS Position to the transducers.

Rawdata storage on board

root directory |

\\polsrv1\data01\fishsounder| |

|---|---|

directory name |

CruiseNo |

file name |

CruiseNo-Dyyyymmdd-Thhmmss.raw |

Data volume (MB per day) ca |

3500 |

Number of files per day ca |

100 |

Dship

Device name |

fishing echo sounder |

|---|---|

Parameters |

depth (18 kHz) [m]; depth (38 kHz) [m]; depth (70 kHz) [m]; depth (120 kHz) [m]; depth (200 kHz) [m] |

Data archiving on land

File format(s) |

*.txt |

|---|---|

Calibration certificates |

NO |

Calibration

The EK80 system must be calibrated. Ideally, the calibration is executed before and after the measurement in the working area. So, the calibration parameters can be defined dependent the actual water conditions. For this reason a calibration on previous cruises will not lead to optimal results.

The calibration is performed using three winch systems positioning the calibration sphere below the transducers.

The winch system as well as their control must operated by the scientists. The laboratory electronic engineer may assist the setup of the system.

A calibration must be planned like all other scrientific work prior the cruise, because the calibration work needs time. Ideally half a day is requested, but will take longer (may be a whole day), if weather conditions decrease.

Ideally the calibration is performed in calm sea without wind. If wind forces the drift of the ship, the winches will not hang vertical anymore but will also drift. Under this conditions it is very difficult, to move the calibration sphere to the requested locations.

Furthermore, the calibration must be planned, because calibration equipment is not permanently on board. The winches etc. need storage capacities and are stored during harbour visit in Bremerhaven, only.

If you are planning to execute a calibration, please add the that work in formula "Einsatzplanung" and step in contact with schiffskoord@awi.de for further planning.

Documentation

-

Simrad EK80 (Web site)

-

Simrad EK80 installation manual (User Manual, 32 MB)

vs. 2021 -

Simrad EK80 reference manual (User Manual, 31 MB)

vs. 2021 -

Simrad EK80 Quick Start Guide (User Manual, 7 MB)

vs. 2021 -

Simrad WBT fact sheet (Factsheet, 1 MB)

vs. 2021 -

Simrad EK80 with ADCP combination (Factsheet, 4 MB)

vs. 2021